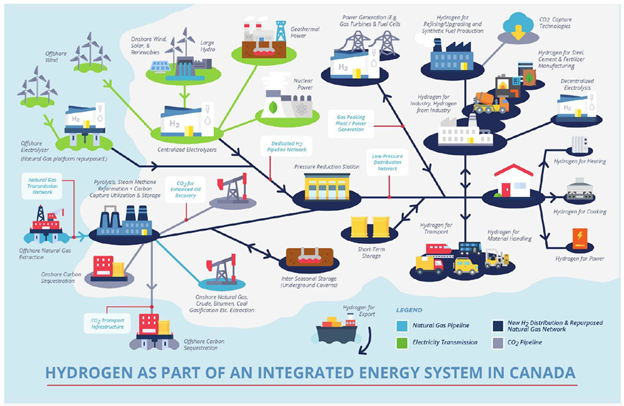

Every so often I’ll read an article on how electric cars are a nice step forward, but the real future is in hydrogen powered cars or the so called ‘hydrogen economy’. Believers in hydrogen technology state that if we can produce hydrogen from only renewable electricity sources, by applying electricity to split water (H2O) molecules into the respective parts — hydrogen and oxygen — and use the hydrogen to fuel vehicles, the result is a vehicle that runs on the reverse reaction and the only tailpipe emission is pure water. Hydrogen technology doesn’t involve any oilsands tailings ponds, mining of lithium or toxic cobalt for batteries, so there are some theoretical advantages. It is also indisputable that water is one of the most abundant molecules on the planet, so there is not issue in finding a water source. The theory sounds nice on paper, but it has many pitfalls and is more like a complicated ‘Rube Goldberg Machine’ when applied to the real world. The reality of producing, compressing, storing, and transporting hydrogen gas is a challenging and expensive technological problem and overcoming the fundamental laws of physics to achieve all of this creates many unique challenges.

Credit: www.nrcan.gc.ca

Electric cars are reasonably affordable today and range in price from $CAD 40,000-$70,000 for a mid-range model with a range of around 500km on a single charge. For a few thousand dollars more, performance models are available that can accelerate from 0-100km/h in under 3.5 seconds. This type of performance was unheard of in anything but the most exotic supercars carrying six-figure price tags even a decade ago.

There are also a handful of hydrogen powered cars on the market today, but these are mostly considered expensive science projects and are only sold in niche markets with heavily subsidized fueling infrastructure. For a similar price of around $USD 60,000 cars like the Toyota Mirai or Honda Clarity are available that can accelerate from 0-100km/h in a relatively pokey 8-9 seconds. While straight line acceleration isn’t the only measure of a car’s performance, even the enormous three-ton Chevrolet Suburban SUV will accelerate from 0-100km/h in around 6 seconds. When merging onto the highway or passing, having a vehicle with a bit of extra pep certainly comes in handy.

Credit: www.Toyota.com

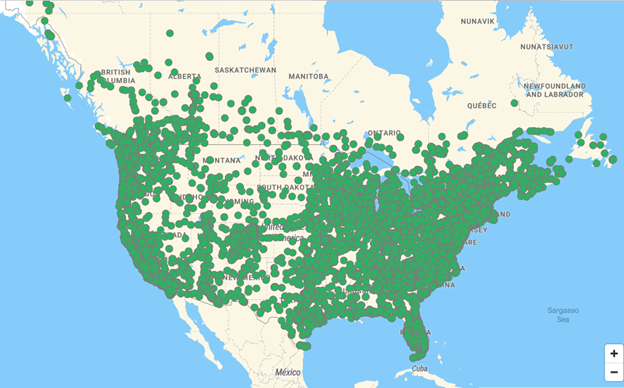

The largest market for hydrogen fuel cell cars is in Southern California where a network of a few dozen hydrogen fueling stations exists in the Greater Los Angeles and San Francisco areas. While these vehicles do have a decent range of between 500-600km, and are well-designed and futuristic looking cars, the scarcity of fueling stations is a big issue for potential buyers. Travel is basically limited to the city limits or immediate surrounding area, as the range wouldn’t allow a driver to travel very far outside the city and make it back home with any margin for delays, like getting stuck in traffic. Some of the manufacturers of these hydrogen powered cars attempt to get around this issue by providing a credit to the buyer for a few weeks’ worth of rentals of gasoline powered cars included with the purchase to allow longer road trips. I’m sure the irony of subsidizing the use of a gasoline powered car with the purchase of a ‘green’ hydrogen powered car doesn’t need to be mentioned.

North American hydrogen fueling stations

Credit: US Department of Energy — Alternative Fuels Data Center

Electric cars do have some drawbacks, but over the past decade, battery technology has improved to the point where storing large amounts of electricity is now possible and building an electric car with a practical range at an affordable price is commonplace. Electric cars do suffer a significant drop in range cold weather, because the onboard systems like cabin heaters, heated seats and keeping batteries warm enough to perform properly puts a large load on an electric car’s battery systems compared to an internal combustion car that uses waste heat from the engine for most of these purposes. With that in mind, battery technology keeps improving and EVs perform well in all but the harshest winter conditions. For city driving, range is rarely an issue, as most drivers conveniently leave the house with a full charge every time as most of the charging happens at home. Even on longer road trips the network of public charging stations is already well-established, and more are being added at a rapid pace. Canada now has over 5,000 public EV charging stations across the country including over 700 DC fast charging stations that allow close to a full charge in around 30 minutes. In a pinch, even an RV campground hookup will allow reasonably fast charging as most camper sites provide a high capacity 220V/30A power supply that will achieve a decent charge in a few hours. The other advantage is that the electrical grid is already well established and new charging stations can be added in nearly any populated area with electricity.

North American EV charging stations

Credit: US Department of Energy — Alternative Fuels Data Center

Will hydrogen powered vehicles ever see widespread adoption?

There are three main issues involved in using hydrogen as a fuel source — transportation, storage and production.

The fundamental characteristics of hydrogen gas make it unsuitable for use as a transportation fuel, as it is highly incompressible, low energy density and explosive in nearly any concentration with air. This makes the transportation and storage of hydrogen a unique challenge. Compressing hydrogen to high pressures requires significant amount of energy and losses to compression can amount to nearly 10% of the energy being stored simply to get it up to storage pressure. Conventional steel or aluminum tanks become embrittled by hydrogen molecules and cannot be used for extended periods before they become unsafe. Compressed hydrogen contains roughly 1/10th energy density of gasoline, therefore a pressurized vessel 10 times larger than a liquid fuel tank would be required to get the same range onboard a vehicle. National Resources Canada recently published a 140-page report that outlines their vision for Canada’s to adopt a comprehensive ‘Hydrogen Strategy’ to help achieve the goal of net zero carbon emissions by 2050. Their own report states that it would cost around $6-$10 per Kg of hydrogen delivered, stored and dispensed at a fueling station, depending on the distance from the source. They don’t bother to convert this to the equivalent cost in terms of gasoline or terms that people can understand (how far can you drive on 1 kg of hydrogen?). One kilogram of hydrogen has roughly the equivalent energy as 3.8 litres of gasoline, so working out the math, it comes out to a delivery and distribution cost of between $1.50 to $2.60 per litre of gasoline equivalent. In my experience, people get cranky when the price of gasoline jumps by even $0.10 per litre before a long weekend, so adding $2 or more per litre to simply cover transportation and distribution costs in addition to the cost of fuel is an obvious non-starter.

The other option for storage and transportation is liquification, which is even more challenging as liquified hydrogen needs to be stored at temperatures below -253C (or approximately 20 degrees above absolute zero — the coldest temperature that is theoretically attainable). This process is even less efficient than compression and can consume up to 30% of the energy value of the fuel to cool the gas to a liquid state (this calculation is also backed by the information provided in the Canadian Government’s NRC Hydrogen Strategy report). Even in liquid form, liquified hydrogen has about ¼ the energy density of gasoline by volume. Therefore, an onboard storage tank would need to be four times larger than a conventional gasoline tank and require significant insulation to keep the hydrogen at super cool temperatures. Keeping hydrogen at this temperature would require continued cooling or it would suffer warming and evaporation losses of 2-3% per day (depending on how well insulated the storage tank is). With this type of evaporation loss, parking a car for a period of even a few weeks would significantly deplete the onboard storage if the vehicle wasn’t driven and refueled regularly.

Proponents will claim that hydrogen by mass has more energy density than gasoline, which is technically true, but factoring in the volume constraints and the fact that a container four times larger for liquified hydrogen (plus insulation) or ten times larger for compressed gas all but negate any potential weight savings.

Photo credit: Transport Topics News

Photo credit: www.TheChemicalEngineer.com

One transport truck or ten transport trucks on the road to achieve the same result?

There is no current pipeline infrastructure of any significance to move hydrogen around from production sites to end users. The same issues listed above would also apply to the bulk transportation of hydrogen as a fuel. Without a pipeline network, diesel powered trucks moving either compressed hydrogen or liquified hydrogen around would be required (This would be a counterproductive move if the end goal is to create a truly ‘green’ system). Either 1/10th the energy for compressed hydrogen or ¼ the energy for liquified hydrogen in each truckload would be delivered, assuming that the trucks and trailers are of a standard size. (Larger vehicles could be used, but going beyond standard load sizes to oversize loads that require cumbersome logistics like escort vehicles, road closures and traffic disruptions is not realistic or practical solution for regular deliveries.)

Producing hydrogen from ‘green electricity’ is even more cost prohibitive. The same Canadian Government report estimates that it costs between $25-$40 to produce one Gigajoule worth of hydrogen with today’s technology. This cost is 12-20x higher than the ~$2/GJ average price of natural gas in Alberta for the past 5 years. This report estimates that with improved hydrogen production technology and increased scale, by 2050 the cost will drop to around $8-$16/GJ, which is still 4x-8x more than the current price of natural gas. I pay a few hundred dollars per month to heat my home with natural gas in the winter months, and it is hard to imagine anyone willingly switching to a fuel option that would cost thousands of dollars per month instead of hundreds.

Photo Credit: Wikipedia (Public Domain)

The most common means of producing hydrogen today is stripping it out of hydrocarbons like natural gas or condensates. Approximately 95% of the hydrogen currently produced is derived from fossil fuel feedstock and is generally produced and consumed on-site in oil refineries, oilsands upgraders or chemical plants for internal processes. Using fossil fuels to produce hydrogen to run a fleet of hydrogen powered vehicles would be far less efficient and more costly than simply using fossil fuels as the fuel source for combustion engine vehicles in the first place. The ‘Rube Goldberg Machine’ depicted above illustrates the idea of building an overly complicated machine to achieve a simple task. Using fossil fuels to produce hydrogen to power a vehicle seems like a similar approach when you include the added complexity and costs involved in production, storage, and distribution.

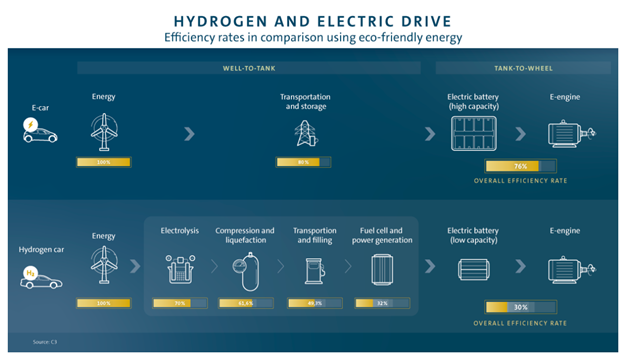

The main proponents of the ‘hydrogen economy’ argue that using off-peak grid power or pairing with renewables and using the electricity to convert water to hydrogen and oxygen is the way to go. The logic stipulates that using off-peak power that would otherwise be wasted is essentially free and this overcomes many of the inefficiencies of the system. This may be true, but it will have to compete with every other way to store electricity like utility scale batteries, pumping water or compressing air. Chemical conversion back and forth introduces entropy losses that can’t be overcome by scale or more efficient methods.

Credit: www.Volkswagenag.com

According to data recently published by Volkswagen (along with touting their new line of EVs) that analyzed the full cycle — from electricity transmission, storage and conversion to power at the wheels of a vehicle — the overall process is between 70-80% efficient for battery electric vehicles. They compared this to hydrogen powered vehicles where they calculate the overall process is between 25%-35% efficient. (For further comparison a modern gasoline or diesel-powered car is between 20%-35% efficient at converting fuel into power.) Batteries continue to improve in performance and energy density, while the fundamental laws of physics limit the efficiency of compressing or liquifying hydrogen gas up to a certain point. While the theory of the ‘hydrogen economy’ is that off-peak power can be used to convert electricity from to hydrogen that would otherwise be wasted, the same can be said for simply storing the electricity in batteries — and not wasting 70% of it. While the Canadian government is keen to pursue a comprehensive ‘Hydrogen Strategy’ and it may look good on paper, the reality is likely to prove out to be another government boondoggle.

The opinions expressed in this report are the opinions of the author and readers should not assume they reflect the opinions or recommendations of Richardson Wealth Limited or its affiliates. Richardson Wealth Limited, Member Canadian Investor Protection Fund. Richardson Wealth is a registered trademark used under license by Richardson Wealth Limited.